Chelsea Middle School student part of major volunteer mask-making effort

Published 3:54 pm Wednesday, April 8, 2020

|

Getting your Trinity Audio player ready...

|

By ALEC ETHEREDGE | Managing Editor

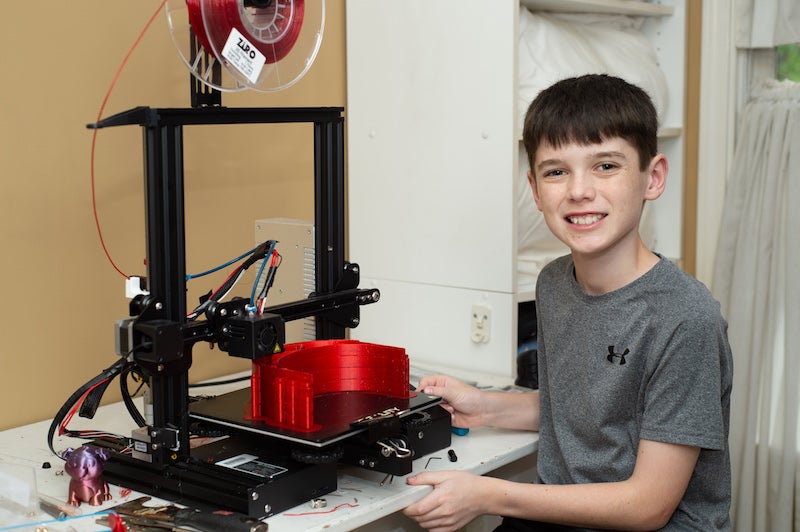

CHELSEA – What started with him taking over his grandfather’s 3D printer two years ago has now turned into making a difference for healthcare workers.

Cooper Swindle, a 12-year-old Chelsea Middle School student, received a 3D printer of his own this past year for his birthday. Opening the gift with excitement, he didn’t know what to expect.

“I was very happy, but honestly I wasn’t sure that the printer was going to be any good because they can be inconsistent,” Swindle said. “But when I started playing with it, the print quality was very good.”

Not only was it good, it is now supplying an important demand. Since schools dismissed due to the spread of COVID-19, Swindle has been stuck at home making face shield masks for doctors and nurses, totaling 25 so far.

“We got text messages and Facebook messages about the need for masks,” mom Stephanie Swindle said. “I said ‘Hey coop, they need some help with 3D printers.’ Before I could even blink, he was online, had the template and got to work.”

Cooper said it usually takes about six hours to make one mask, but he has been printing them in stacks of four, which typically takes about a day.

“There just isn’t much else to do and I just want to help the doctors,” he said. “I know they’re dealing with a lot, and I just want to give them protection and help stop the spread.”

Once he knew there was a need, he said there was no reason to hesitate in making the masks.

“If I keep printing designs that won’t really help, it would be no use, but if I can print these masks and get them to doctors, I can help them,” Cooper said.

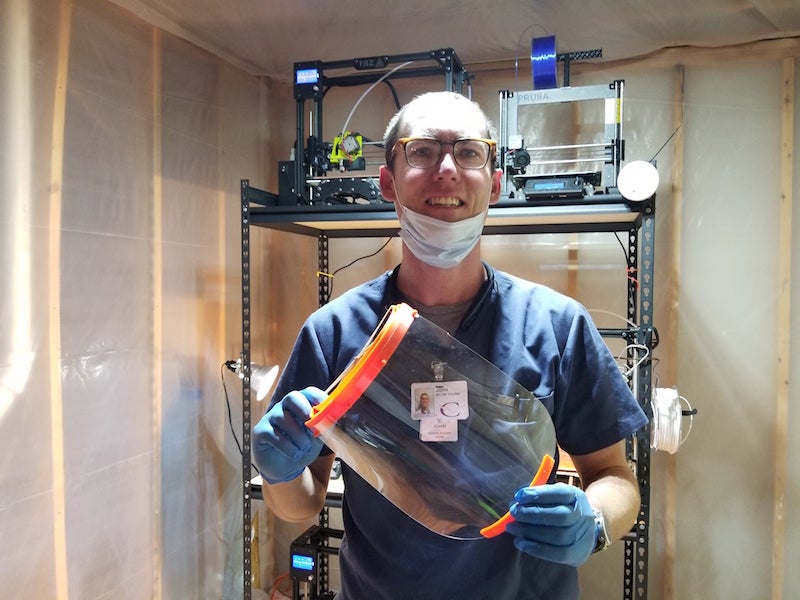

His help is somewhat of a trickle effect from a volunteer program started by another North Shelby County resident named John Olsen.

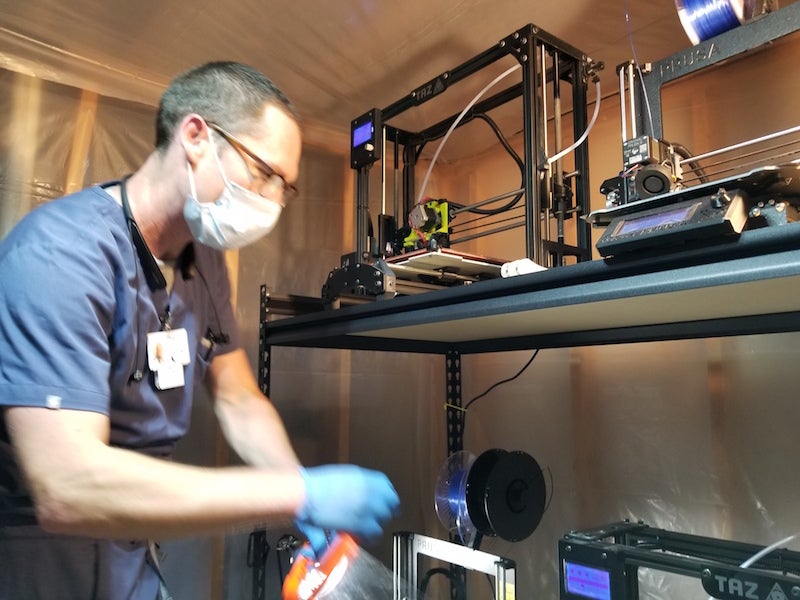

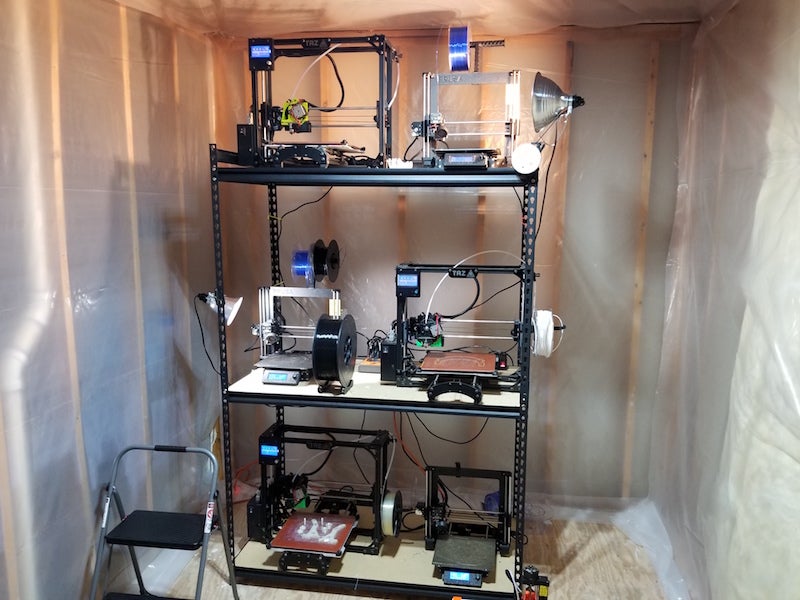

A medical student with his own 3D printers at home, Olsen got to work in his basement two weeks ago.

“I thought I could make them for my nurse and doctor friends and maybe take some down to the UAB testing site, but then I made a Facebook post to see who might need some and that’s when it took off,” Olsen said.

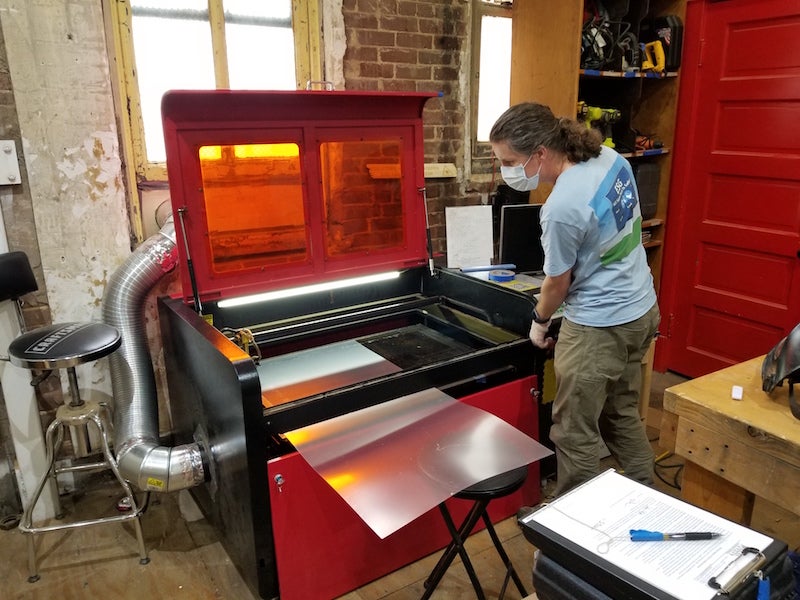

Following that post, Olsen got a message from Shirley Hicks, who co-founded Red Mountain Makers, which is a non-profit organization that helps promote exploration of STEAM (Science, technology, engineering, art and mathematics) using items like 3D printers.

“I was just asking for a vinyl cutter to help make these masks and she immediately said I wouldn’t be able to make enough that way,” Olsen said. “She’s the one that got me thinking big picture.”

With Hicks’ network of people that she knows from Red Mountain Makers, they were able to get suppliers on board to donate items and help produce masks and thus Bham Support was born.

“Industrial and manufacturer contacts got on board who are running companies with 300-400 employees. Their answers have all been a resounding yes,” Olsen said. “They’ll help and they’re not worried about the cost of it all because of the cause.”

Bham Support brings together a community of 3D printers around the Birmingham area, based solely on volunteers, to help produce the face shield masks for healthcare employees in the metro area, including Shelby Baptist in Alabaster.

“It’s never been about one big fancy building with 100 printers. It’s always been 100 people like Cooper out there that can deliver a half dozen a day,” Olsen said. “We’re thinking about delivering four, five, six at a time.”

Olsen said the main goal is to keep the healthcare system from collapsing on itself by keeping the staff safe. He said that he worries about half of an eight-person nursing staff getting the virus.

“That keeps me up at night,” he said. “We’re adding more on top of an overburdened system. The staff is stretched thin and short staffed as it is. You still have people getting sick, having heart attacks, giving birth, having strokes and dealing with diabetes. And now you add this on top of it.”

Right now, Olsen said there are an untold number of people with 3D printers volunteering their time to help, but he is hoping that more with the device will put it to work and join Bham Support’s cause for donating the shields.

“Right now, we have two dozen people working actively fullish time,” he said. “Half are makers running 3D printers cranking out, while others we have working are more for the structure, planning and coordination side of things.”

In addition to those, there are several others also volunteering when they can, but Olsen wants to make sure if you have a 3D printer that you know you can help as well.

Bhamsupport.com offers options to donate and volunteer, while those in the healthcare industry can share what they are in need of.

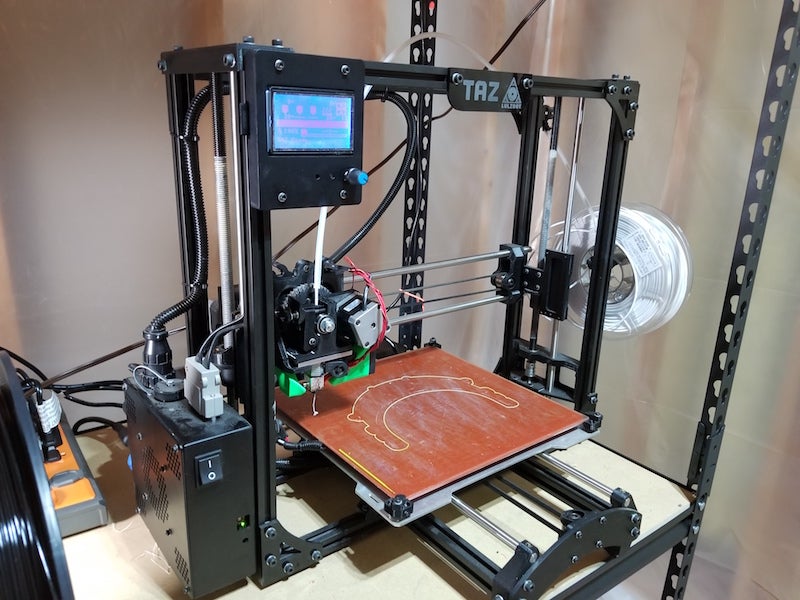

He also said the focus right now is to produce face shields rather than N95 masks or other types of PPE.

“I saw people trying to immolate N95 masks, ventilators and also the face shields,” he said. “I was interested in all of them of course, but the face shield was the one I thought would be easy enough to make and share.”

With N95 masks meant to stop 95 percent of particulate matter, Olsen said there is still that 5 percent that germs can get through if somebody sneezes or coughs near your face, even if you’re wearing the mask properly.

And for 3D printers, he said it would turn out more like an N80 or N70 mask that wouldn’t be as effective.

“The face shield just adds that extra layer of protection, and I realized we could do it safely and quickly,” Olsen said.

He added that his opinion is that the shields they are making are better that what is currently coming down the supply chain.

“Our masks are designed with PETG (Polyethylene terephthalate glycol) material, which is chemically resistant,” he said. “It will hold up to anything chemically, while others are thrown away after one use.”

He said healthcare employees can use the shield in addition to masks and other PPE gear, which can help completely keep the germs away.

As a project that started in his basement, Bham Support has now made its way to many volunteers like Cooper Swindle and others looking to offer their time for a good cause, which Olsen is extremely thankful for.

“I haven’t met Cooper or had a conversation with him, but what he’s making and it being a perfect 3D print, it’s impressive,” Olsen said.

Right now, 30 hospitals and clinics have asked for supplies around the metro area, and the help of Cooper and others stepping up as volunteers for Bham Support are supplying an important chain of demand.