MHS teacher, student utilize 3D printer to make PPE items

Published 1:47 pm Thursday, April 23, 2020

- Montevallo High School senior Miranda Martin and her father, Michael, have been 3D printing face masks and other personal protective equipment pieces for health care workers and first responders. (Contributed)

|

Getting your Trinity Audio player ready...

|

By EMILY SPARACINO / Staff Writer

MONTEVALLO – A Montevallo High School math teacher and his daughter have joined in on efforts to make personal protective equipment for health care workers and first responders.

Michael Martin and his daughter, Miranda, a senior at MHS, saw a friend’s social media post about 3D printing components for a face shield and thought they could help combat the PPE shortage in the same way.

“We thought it would be a great way to utilize the printer we obtained for the underwater ROV/robotics team we started this year that didn’t get to compete,” Michael said. “Unfortunately, we needed a contact who could help with logistics so we could hit the ground running.”

The next day, the Martins saw a post about the University of Montevallo’s efforts to print PPE.

They reached out to UM Digital Media and Emerging Technologies Librarian Michael Price, got permission to use the printer from the high school’s administration and have been printing ever since.

Miranda, who said she has a passion for STEM activities, was already comfortable with the printer after using it to print claws and cases for the Underwater ROV team’s robot.

“My dad taught me how to design the claws, and I helped print them out so we can attach them to the motor that is attached to the robot,” she said.

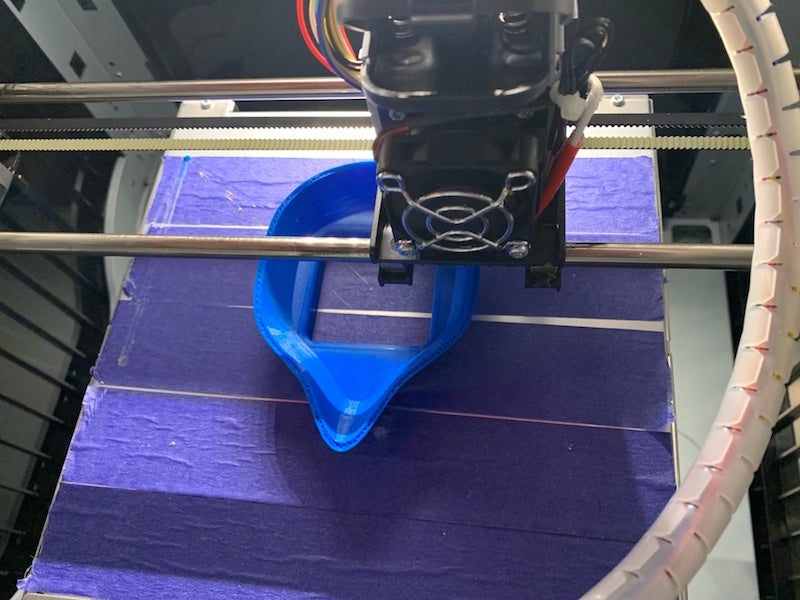

Michael and Miranda Martin are using the MHS Underwater ROV/Robotics Team’s printer to make face masks and components for other types of PPE. (Contributed)

The Martins have printed more than 200 items, including masks, face shields and other types of PPE.

Collectively, the team has distributed more than 1,000 items.

“The partnership with UM has been great, and we are stronger as a team,” Michael said. “It takes many individuals and many printers to try to keep up with the demand.”

Each mask has two pieces and requires about five hours of print time. A face shield, depending on the model and components, can take two to four hours.

Printing is happening 24 hours a day, seven days a week, Michael said.

He and Miranda take turns setting up various print jobs, removing and prepping the printed items, changing filament and troubleshooting any problems that might occur.

“It is all about helping others,” Michael said. “Find a need, meet a need. Every day we are faced with events that we have no control of that may bring anxiety to our lives. The key is finding the courage to change the things you can change and work together to make a difference.”

The Martins have received requests from near and far away. They have supplied face shields to local facilities, such as Shelby Baptist Medical center and Shelby Ridge.

They have fulfilled requests from firefighters in Decatur and hospital staff in Mobile, plus multiple locations across the state.

“We have had people contact us who were literally crying in need,” Michael said. “All have been very appreciative.”

Miranda said helping others has made her feel better about the situation.

“I have enjoyed every moment of this, and I am glad that I am able to be a part of something that is literally helping the world,” she said. “I am so thankful for everyone in the medical field and in other fields that are working through this pandemic, and I hope that in the future we can look back on this and see how much closer it brought everyone in everyone’s time of need.”